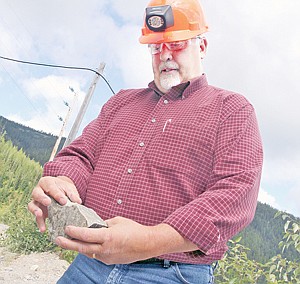

Revett operation focuses on maximizing ore extraction, safety

|

September 5, 2012 1:06 PM

What exactly is a miner? If you thought like the staff of The Western News the other day when we got a tour of the Troy Mine, you might have thought it was the gritty, soot-covered men of yesteryear or the whistling pick-axe wielding dwarves of Disney.

What we discovered instead was surprising. Only 40 percent of employees at Revett Minerals’ Troy Mine even go underground. The employees are well-versed and trained in proactive safety measures and the finished product from the mine is a fine-grained sand-like material with copper and silver within.

From the administrative offices to the workshop to the well-ventilated shaft itself, Troy Mine is a safety-first operation.